リチウム バッテリーを扱う場合、電気自動車、太陽光発電システム、その他の用途を問わず、バッテリー端子の適切なトルクを確保することが非常に重要です。これは、バッテリーの性能と効率に影響するだけでなく、安全性にも重要な役割を果たします。このブログ投稿では、リチウム バッテリー端子のトルクの重要性、推奨されるトルク仕様、および従うべきベスト プラクティスについて詳しく説明します。

トルクが重要な理由

-

電気接続: 適切なトルクにより、バッテリー端子の電気接続が確実に強化されます。これにより抵抗が最小限に抑えられ、エネルギー損失が低減し、バッテリー システム全体の効率が向上します。

-

安全性: 端子を締めすぎたり締め付けが不十分だと、重大な安全上の問題が生じる可能性があります。締め付けが不十分だと、端子やバッテリー自体が損傷する可能性があり、締め付けが不十分だと、接続が緩んだり、火花が発生したり、火災の危険が生じる可能性があります。

-

長寿命: 正しいトルクは、長期間にわたってバッテリー端子の完全性を維持するのに役立ちます。適切に固定された端子は、自動車や再生可能エネルギーの用途でよく見られる振動や熱膨張および収縮によって緩む可能性が低くなります。

推奨トルク仕様

リチウム電池端子のトルク仕様は、電池の設計と製造元によって異なります。

標準ボルトの締め付けトルクは次のとおりです。

| 強度等級 | 降伏強度(N/mm²) | 公称直径(mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | ||

| 締め付けトルク (Nm) | |||||||||

| 4.8 | 240 | 4-5 | 10-12 | 20-25 | 36-45 | 55-70 | 90-110 | 120-150 | 170-210 |

| 5.6 | 300 | 5-7 | 12-15 | 25-32 | 45-55 | 70-90 | 110-140 | 150-190 | 210-270 |

| 6.8 | 480 | 7-9 | 17-23 | 33-45 | 58-78 | 93-124 | 145-193 | 199-264 | 282-376 |

| 8.8 | 640 | 9-12 | 22-30 | 45-59 | 78-104 | 124-165 | 193-257 | 264-354 | 376-502 |

| 10.9 | 900 | 13-16 | 30-36 | 65-78 | 110-130 | 180-201 | 280-330 | 380-450 | 540-650 |

| 12.9 | 1080 | 16-21 | 38-51 | 75-100 | 131-175 | 209-278 | 326-434 | 448-597 | 635-847 |

ただし、一般的なガイドラインは次のとおりです。

-

自動車用リチウム電池: 通常、トルク仕様は 5 ~ 15 Nm (ニュートンメートル) の範囲です。正確な値については、バッテリー製造元の仕様を参照することが重要です。

-

大型産業用または太陽電池: これらには、通常 10 ~ 25 Nm の範囲のより高いトルク値が必要になる場合があります。この場合も、特定のバッテリーのマニュアルを参照することが重要です。

これらの値は一般的な推定値であることに注意してください。最適なパフォーマンスと安全性を確保するには、特定のバッテリー モデルの製造元のガイドラインに常に従ってください。

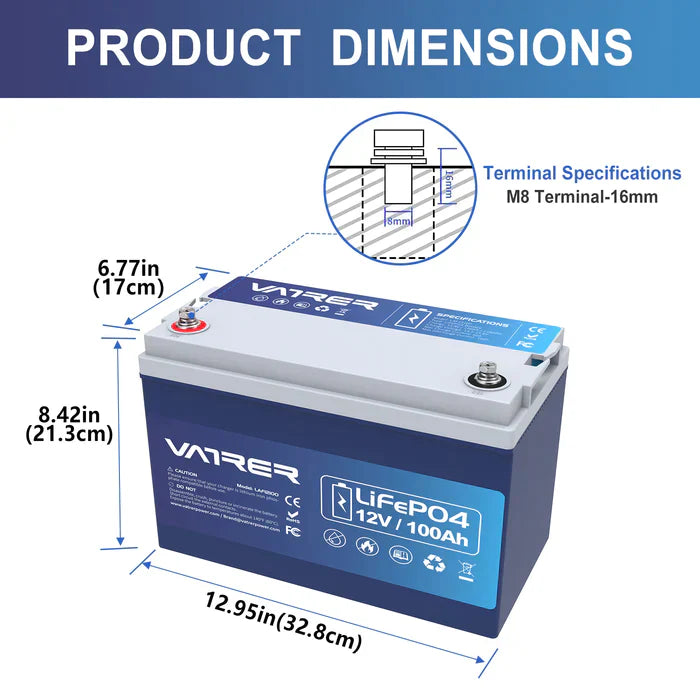

* Vatrer Power リチウム電池は、強度等級 5.6 に数値的に近い強度等級 5.8 のネジを使用しています。

トルク適用のベストプラクティス

-

適切なツールを使用する: バッテリー端子を締める際にはトルクレンチを使用します。これにより、多すぎず少なすぎず、適切な量のトルクを適用できます。

-

製造元のガイドラインを確認する: 具体的なトルクの推奨事項については、必ずバッテリーのマニュアルまたは製造元の Web サイトを確認してください。モデルやメーカーによって要件が異なる場合があります。

-

定期メンテナンス: 定期メンテナンスの一環として、バッテリー端子のトルクを定期的にチェックしてください。これは、車両など、バッテリーが振動を受ける環境では特に重要です。

-

環境条件に注意してください: 温度変動などの要因は、端子接続の密閉性に影響を与える可能性があります。定期的にチェックすることで、熱膨張や収縮によって生じる問題を防ぐことができます。

-

安全第一: バッテリーを扱うときは、常に適切な安全装備を着用してください。感電やショートを防ぐため、電源がオフになっており、システムが接地されていることを確認してください。

結論

リチウム バッテリーの端子に適切なトルクを理解して適用することは、バッテリー システムの効率、安全性、寿命を維持するために重要です。製造元のガイドラインに従い、定期的なメンテナンスを実施することで、リチウム バッテリーがスムーズかつ安全に動作することを保証できます。自動車愛好家、再生可能エネルギーの支持者、さまざまな用途でバッテリー電源に依存している人など、トルクに注意を払うことで、システムのパフォーマンスに大きな違いが生じる可能性があります。