Table of Contents

- 1. Introduction

- 2. Common Issues in Lithium Conversion

- 2.1 Voltage Compatibility Problems

- 2.2 Battery Management System (BMS) Conflicts

- 2.3 Motor Overheating

- 2.4 Wiring and Connection Challenges

- 3. Specific Case Studies

- 3.1 LIDO Golf Cart Conversion Issues

- 3.2 Yamaha Lithium Battery Conversion Problems

- 3.3 EZGO Golf Cart Lithium Battery Problems

- 4. Troubleshooting Common Problems

- 5. Recommendations for Successful Conversion

- 5.1 Proper Battery Selection

- 5.2 Compartment Adjustments and Reinforcements

- 5.3 Regular Maintenance and Monitoring

- 6. Conclusion

1. Introduction

1.1 Overview of Golf Cart Lithium Conversion

The transition from traditional lead-acid batteries to lithium batteries in golf carts has gained significant traction in recent years. Lithium batteries offer numerous advantages, including lighter weight, longer lifespan, faster charging times, and improved energy efficiency. However, the conversion process is not without its challenges. Understanding these challenges is crucial for golf cart owners considering this upgrade.

1.2 Importance of Understanding Conversion Issues

As the popularity of lithium batteries continues to rise, so does the need for awareness regarding potential issues that may arise during conversion. Identifying and addressing these problems can enhance performance, extend battery life, and ensure a smoother transition. This report aims to provide a comprehensive overview of the common issues associated with lithium conversion in golf carts, along with case studies and troubleshooting recommendations.

2. Common Issues in Lithium Conversion

2.1 Voltage Compatibility Problems

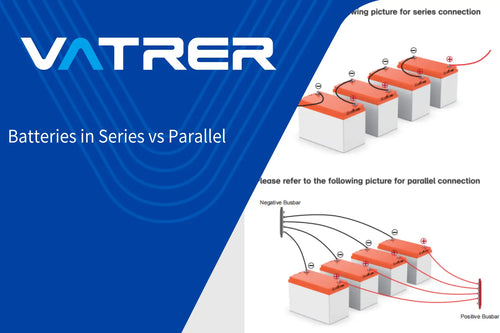

One of the primary challenges encountered during lithium battery conversion is voltage compatibility. Lithium batteries operate at different voltage levels compared to lead-acid batteries. For instance, a typical lead-acid battery system may operate at 36V or 48V, while lithium batteries may have varying nominal voltages (e.g., 12V, 24V, 36V). This discrepancy can lead to performance issues, including insufficient power delivery to the motor or potential damage to the electrical system if not properly managed.

2.2 Battery Management System (BMS) Conflicts

The Battery Management System (BMS) is a critical component in lithium battery systems, responsible for monitoring and managing the battery's performance. Conflicts may arise when integrating a new lithium battery with an existing golf cart system that was designed for lead-acid batteries. Issues such as incorrect BMS settings, incompatibility with the cart's controller, or failure to communicate effectively can result in power cut-offs, reduced performance, or even battery damage.

2.3 Motor Overheating

Another significant concern during lithium conversion is motor overheating. Lithium batteries can deliver higher currents than lead-acid batteries, which may lead to increased heat generation in the motor. If the motor is not adequately rated for the higher power output, it may overheat, leading to potential failure. Proper assessment of the motor's specifications and compatibility with lithium batteries is essential to mitigate this risk.

2.4 Wiring and Connection Challenges

The conversion process often involves modifications to the wiring and connections within the golf cart. Inadequate wiring or poor connections can lead to voltage drops, increased resistance, and ultimately, performance issues. Ensuring that all connections are secure and that the wiring is appropriately rated for the new battery system is crucial for maintaining optimal performance.

3. Specific Case Studies

3.1 LIDO Golf Cart Conversion Issues

A case study involving a 48V LIDO golf cart conversion highlights several common issues. After installing lithium batteries, the owner reported a complete lack of power to the motor. Upon investigation, it was determined that the wiring connections were not compatible with the new battery system, leading to a failure in power delivery. This case underscores the importance of thorough wiring assessments during conversion.

3.2 Yamaha Lithium Battery Conversion Problems

In another instance, a Yamaha golf cart experienced performance degradation post-conversion. The owner noted that the cart ran slower than expected, and the BMS frequently cut off power during acceleration. This issue was traced back to incorrect BMS settings that were not calibrated for the new lithium batteries. Adjusting the BMS settings resolved the performance issues, demonstrating the critical role of proper configuration.

3.3 EZGO Golf Cart Lithium Battery Problems

An EZGO golf cart conversion revealed issues with abrupt power loss when the accelerator was released. This problem was linked to regenerative braking systems that were not compatible with the lithium battery setup. The owner had to modify the braking system to accommodate the new battery technology, illustrating the need for comprehensive system evaluations during conversion.

4. Troubleshooting Common Problems

4.1 Diagnosing Power Issues

When diagnosing power issues in a converted golf cart, it is essential to check the following:

-

Battery Voltage: Ensure that the lithium batteries are fully charged and functioning correctly.

-

Wiring Connections: Inspect all wiring for secure connections and signs of wear or damage.

-

BMS Functionality: Verify that the BMS is correctly configured and communicating with the cart's controller.

4.2 Addressing Performance Degradation

If performance degradation is observed, consider the following steps:

-

BMS Calibration: Recalibrate the BMS settings to match the specifications of the lithium batteries.

-

Motor Assessment: Evaluate the motor's compatibility with the new battery system and consider upgrading if necessary.

-

Load Testing: Conduct load tests to identify any potential bottlenecks in the system.

4.3 Solutions for BMS Cut-Offs

To address BMS cut-offs, it is crucial to:

-

Adjust Cut-Off Settings: Modify the cut-off voltage settings within the BMS to align with the lithium battery's specifications.

-

Monitor Temperature: Ensure that the battery and motor temperatures are within acceptable ranges to prevent thermal cut-offs.

-

Regular Maintenance: Implement a regular maintenance schedule to monitor battery health and system performance.

5. Recommendations for Successful Conversion

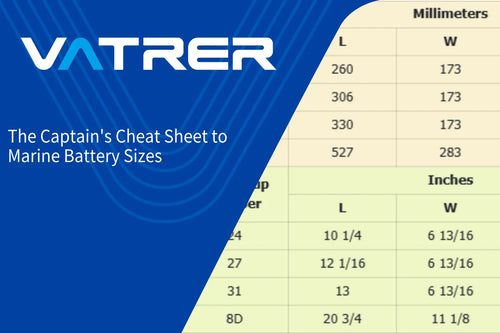

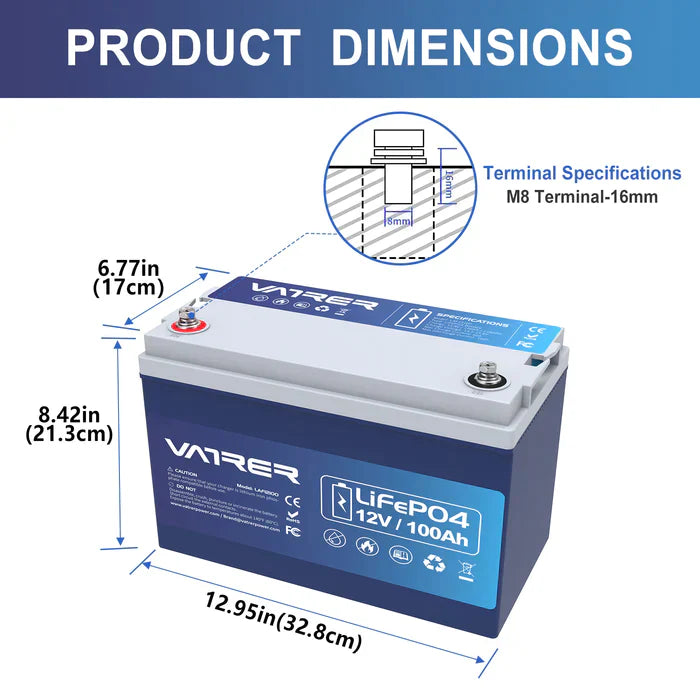

5.1 Proper Battery Selection

Selecting the right lithium battery is paramount for a successful conversion. Consider factors such as voltage compatibility, capacity, and discharge rates. It is advisable to choose batteries specifically designed for golf cart applications to ensure optimal performance.

5.2 Compartment Adjustments and Reinforcements

When installing lithium batteries, it may be necessary to make adjustments to the battery compartment. Reinforcing the compartment can prevent movement and damage during operation. Additionally, ensuring proper ventilation is essential to dissipate heat generated during charging and discharging.

5.3 Regular Maintenance and Monitoring

Establishing a routine maintenance schedule is vital for the longevity of lithium batteries. Regularly check battery health, wiring connections, and BMS functionality. Monitoring performance metrics can help identify potential issues before they escalate.

6. Conclusion

6.1 Summary of Key Points

The conversion of golf carts from lead-acid to lithium batteries presents several challenges, including voltage compatibility, BMS conflicts, motor overheating, and wiring issues. Understanding these challenges is essential for successful conversion and optimal performance.

6.2 Future of Lithium Conversions in Golf Carts

As technology advances, the future of lithium conversions in golf carts looks promising. Continued improvements in battery technology, coupled with increased awareness of conversion issues, will likely lead to more efficient and reliable golf cart systems. Golf cart owners are encouraged to stay informed and seek professional assistance when considering lithium battery conversions to ensure a smooth transition.

1 comment

Lutz Keidel

Ich habe bei meinem Golfcart EZ-GO TXT, daß von Ihnen beschriebene Problem, daß nach der Umrüstung auf Lithium nichts geht. Was muß ich tun bzw. brauche ich, daß das Biest wieder läuft.

Für eine Antwort wäre ich mehr wie dankbar.

Ich habe bei meinem Golfcart EZ-GO TXT, daß von Ihnen beschriebene Problem, daß nach der Umrüstung auf Lithium nichts geht. Was muß ich tun bzw. brauche ich, daß das Biest wieder läuft.

Für eine Antwort wäre ich mehr wie dankbar.